Overview

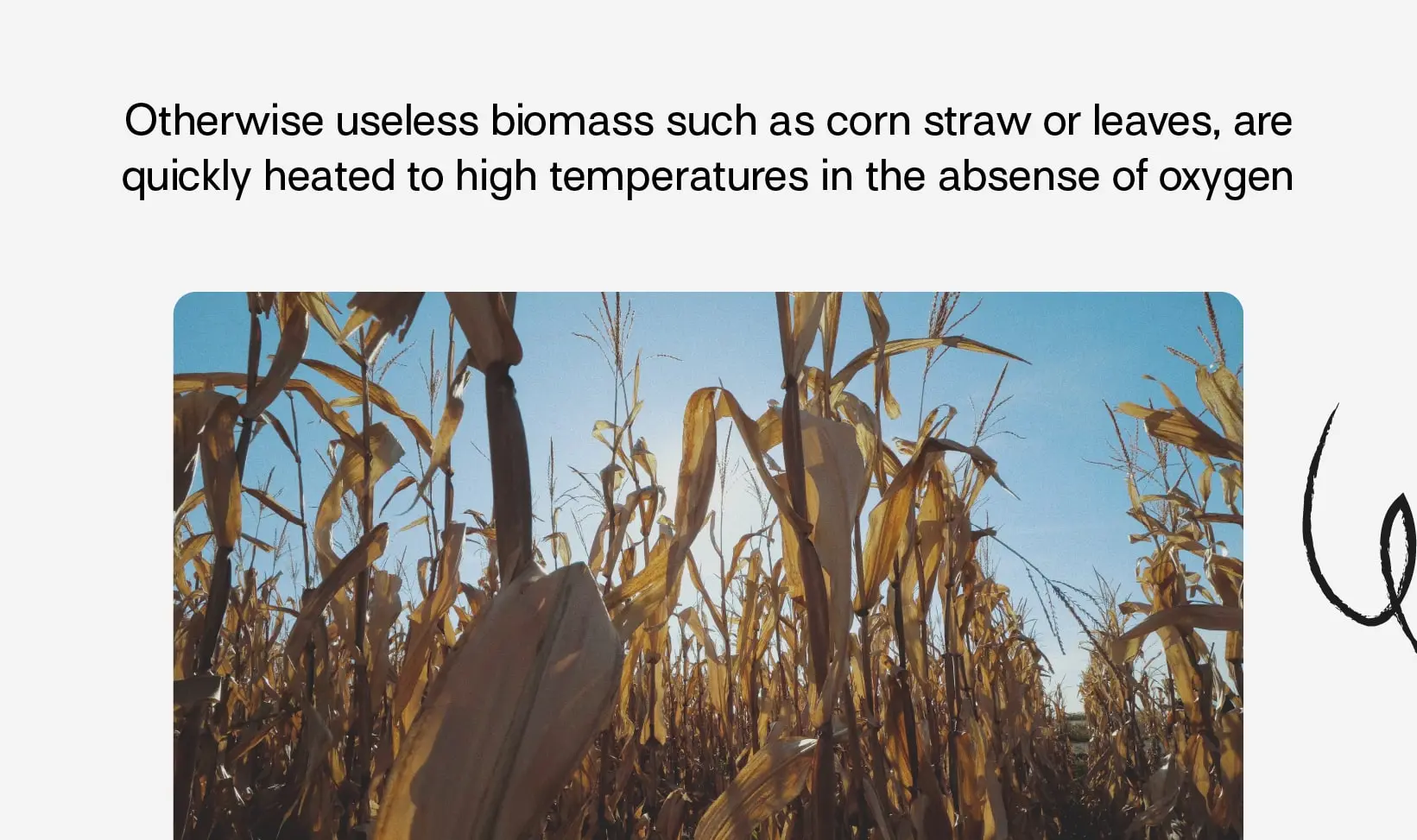

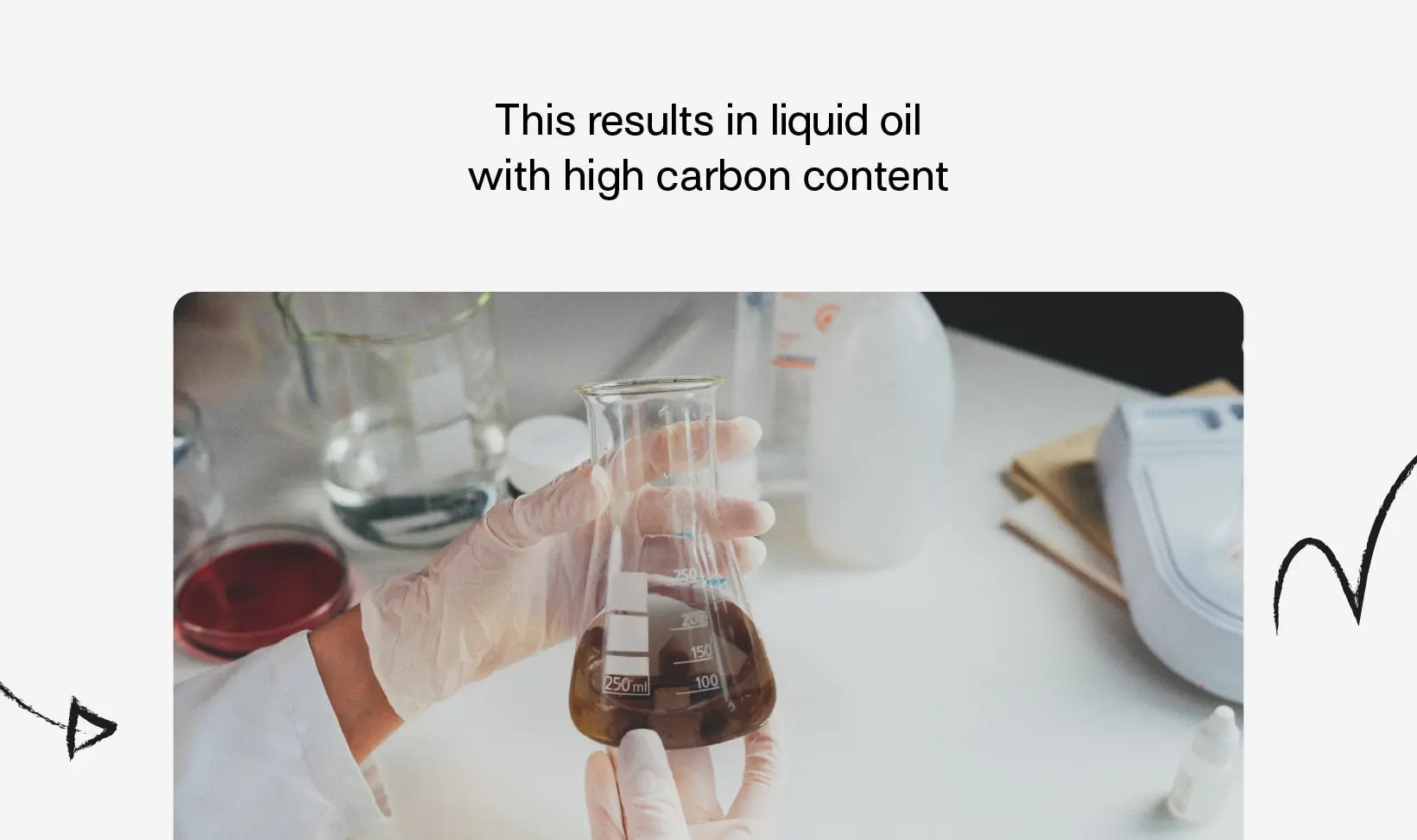

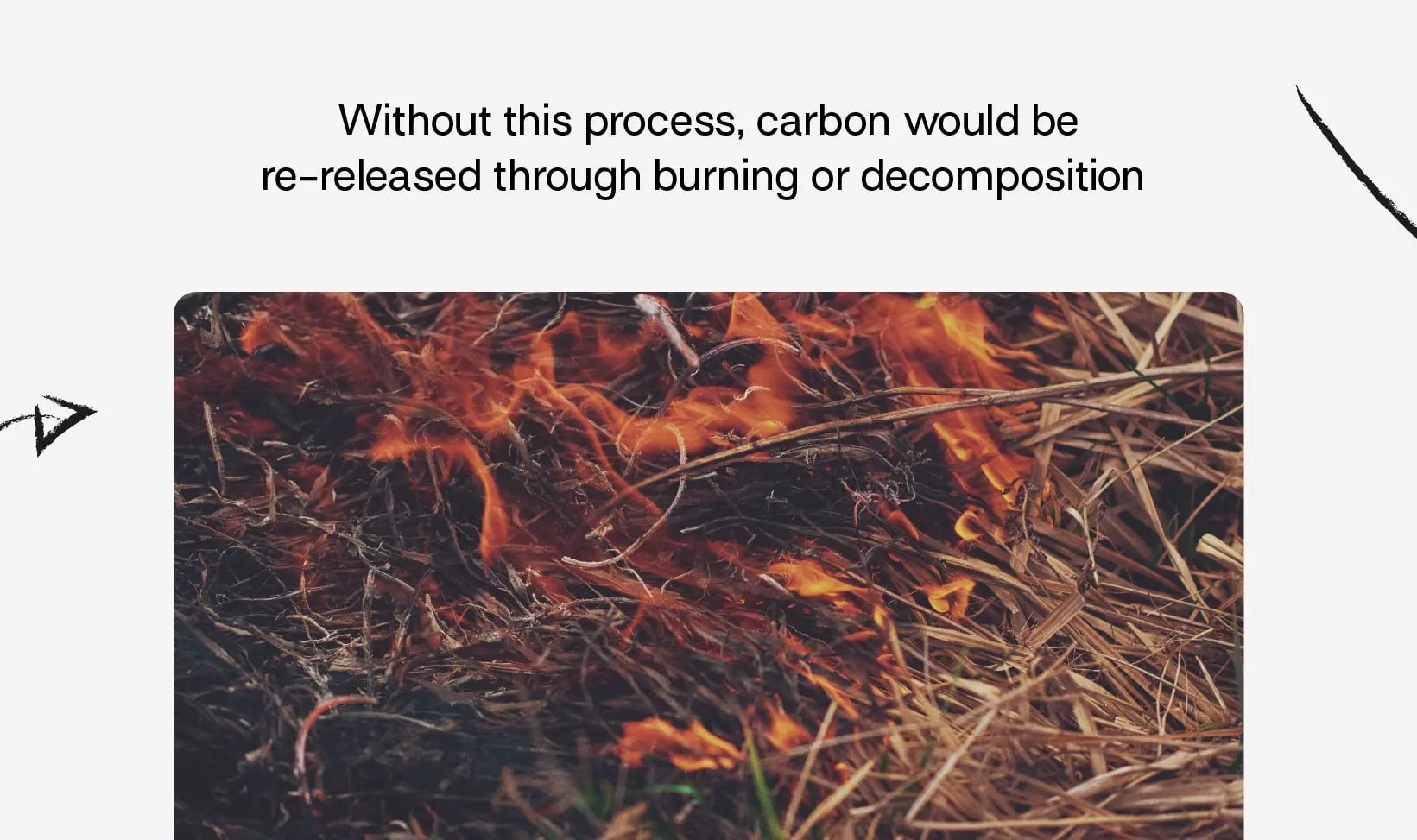

Bio-oil has some similarities with biochar production. They both take waste or spare biomass and convert it to a highly stable form in a high temperature environment through pyrolysis process. The difference with bio-oil is that the result is liquid, and instead of being applied to soils, it is pumped in geological storage, where it’s highly likely going to stay permanently.

With a bit of help from plants (which to the removing from the atmosphere part) this process is therefore putting oil back into the ground.